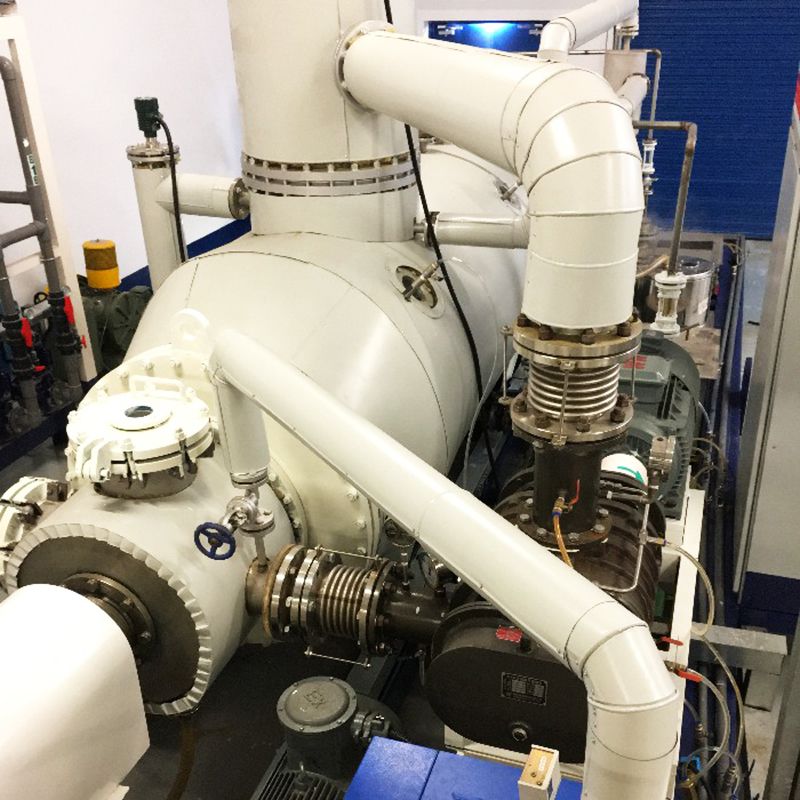

Mechanical Vapor Recompression Evaporator

Working Principle of MVR Evaporator

The secondary steam evaporated from the evaporator is compressed by the compressor, and the pressure and temperature are increased. Then it returns back to the heating chamber of the evaporator and is used as the heating medium to keep the liquid material at the boiling state. After heat exchange process, the heating steam is condensed into water, so that the secondary steam is fully utilized, achieving high heat efficiency.

Features

- No need for steam evaporation, the evaporation can be accomplished by recovering the heat of secondary steam and mechanical compression;

- No need for condensing system and cooling water to cool the secondary steam, greatly reducing public supporting facilities and saving energy;

- Low temperature evaporation can be realized, suitable for evaporation and concentration of heat sensitive materials;

- Extremely low energy consumption, the minimum power consumption of evaporation per ton of water is only 30kW;

Hecheng has developed a variety of MVR evaporators including MVR falling film evaporator, MVR forced external circulation evaporator and patented MVR built-in rotary evaporator, to greatly reduce the operating cost of equipment for customers. Hecheng makes good use of energy for you.

Get in Touch